Fabrication of mechanically robust nanoporous ZrSiO4 ceramics at low temperature with a low doping level of Mn dopant

发布时间:2024-01-04

点击次数:

DOI码:10.1111/ijac.14652

发表刊物:International Journal of Applied Ceramic Technology

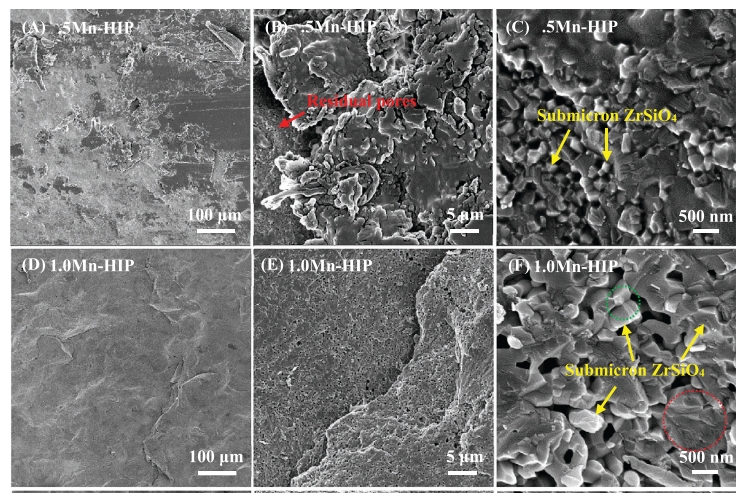

摘要:Zircon (ZrSiO4) ceramics have been widely used in many fields due to their excellent physical and chemical properties. However, ZrSiO4 ceramics typically possess moderately low mechanical properties, which hinders their wider application. Meanwhile, elevated temperatures (∼1500°C) are required to obtain high-purity synthetic ZrSiO4 ceramics, which is time- and energy-consuming. In the present study, we prepared mechanically robust ZrSiO4 ceramics at low temperature (∼1170°C) with a low doping level of Mn dopant (<2 mol%). The ZrSiO4 ceramic processed by hot isostatic pressing with .5 mol% Mn dopant achieved the highest flexural strength (512 MPa), elastic modulus (341 GPa), and nanohardness (20.8 GPa). These values are significantly higher than conventional ZrSiO4 ceramics. The strengthening mechanisms of the prepared ZrSiO4 ceramics were attributed to the formation of homogeneously-distributed nanopores due to incomplete densification and submicron ZrSiO4 grains (∼300 nm). The nanopores avoided stress concentration and deflected microcracks during loading, and the submicron ZrSiO4 grains endowed the ZrSiO4 ceramics with grain refinement strengthening. The results reported in this study would offer guidance to fabricate mechanically robust ZrSiO4 ceramics at low temperatures with a low doping level of dopant.

合写作者:Huasi Zhou, Lena Klintberg, Hakan Engqvist

第一作者:Le Fu

通讯作者:Wei Xia

卷号:21

页面范围:1954-1964

是否译文:否

发表时间:2024-01-04

收录刊物:SCI

发布期刊链接:https://ceramics.onlinelibrary.wiley.com/doi/10.1111/ijac.14652