席昭论文"Effect of copper and iron substitution on the structures and electrochemical properties of LiNi0.8Co0.15Al0.05O2 cathode materials"被Energy Science & Engineering接收发表

发布时间:2020-04-25

点击次数:

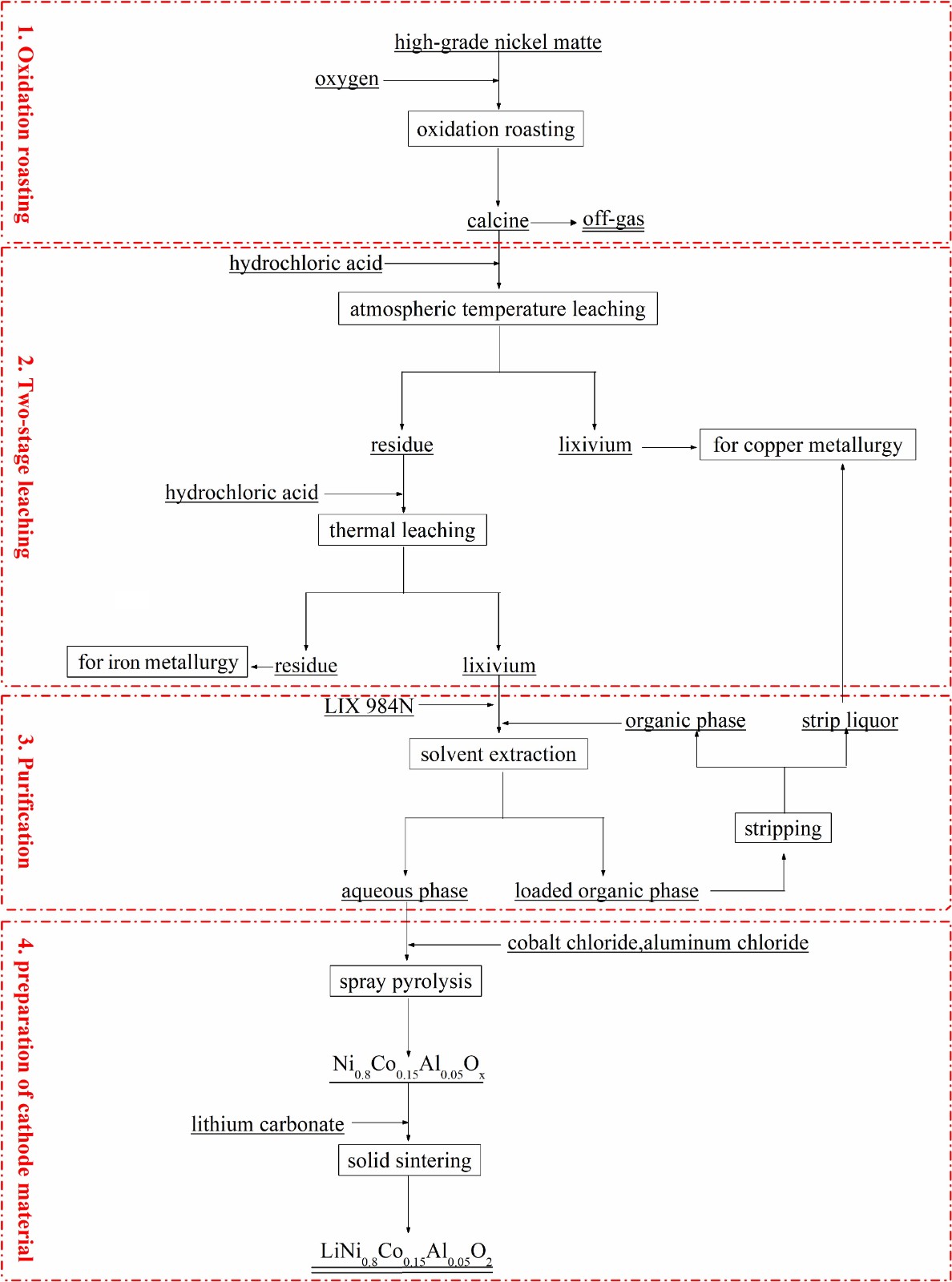

In this study, an material-oriented metallurgical strategy, which is of such characteristics as short process, energy conservation and cost saving, is proposed to treat high-grade nickel matte and simultaneously produce LiNi0.8Co0.15Al0.05O2 cathode material for lithium ion batteries. This process mainly composes of four steps of oxidation roasting, two-stage leaching, purification and material synthesis. First, high-grade nickel matte is roasted to eliminate sulfur. Then the calcine is first leached to selectively remove 78.10% Cu with little Ni and Co extraction at atmospheric temperature under optimum conditions (temp. 25 ℃, HCl 1.50 mol L-1, L/S 7.0, 30 min). After that, 96.23% Ni, 96.58% Cu and 84.18% Co are extracted in thermal leaching process under optimum conditions (temp. 70 ℃, HCl 3.0 mol L-1, L/S 10.0, 120 min), leaving Fe, Zn and Ca in residue. The obtained lixivium is purified by solvent extraction method to adjust the mass ratio of Cu/Ni to the range that meets the requirement for preparation of cathode material. Finally, LiNi0.8Co0.15Al0.05O2 material is produced by spray pyrolysis and sintering. The electrochemical performance of the resulting material is comparable with that prepared from analytical reagents, indicating such process can realize the comprehensive utilization of high-grade nickel matte.