Available projectsNote for research higher degree(RHD) candidates: The available research projects listed on this page may not be comprehensive or up to date. Always feel free to contact Dr. Zhilin Liu for more information, and also with your own research ideas. Innovation is encouraged in my group, as is independent thing of knowldege leadership. I am always standing here open for discussing any innovation-driven ideas. Currently, I am supervising 3 PhDs, 4 MPhil students, and 2 B.Eng students on my own projects.

(1) Crystallography of phase transformations in solid crystalline materials To produce metallic materials with high performance, understanding of phase transformations is essential because they control the microstructures that govern the properties. The project aims to develop a unified crystallographic theory through integration of the current two models based on an innovative approach of regarding the different transformations as part of a continuous spectrum. The new theory overcomes the deficiencies and weaknesses of current models/theories and provides a comprehensive understanding of phase transformations. The research impacts the field of physical metallurgy by generating new scientific knowledge. It clarifies and eliminates decades of controversy associated with the displacive-diffusional and massive transformations. Three unique techniques will be employed for crystallographic study in this research topic, including (a) convergent beam Kikuchi line diffraction pattern (CBKLDP) technique, (b) edge-to-edge crystallographic matching (E2EM) model and its relevant analysis software (unique technique), and (c) orientation relationship (OR) determination using EBSD patterns and the Euler-based numerical method.

(2) Novel approach to grain refinement of cast metals and alloys (in particular for biodegradabe Zn alloys) In terms of grain refinement, the recently-developed new theories, i.e. edge-to-edge matching (E2EM) model and Interdependenc theory, will be applied to design and fabricate efficient grain refiners fo cast metals/alloys. E2EM model and Intredependence theory are recent breakthrouhg to elucidate grain initiation, growth, nucleant selection and solute effect in grain refinement. Meanwhile, grain refinement of large-scale cast is a new challenge research field. Grain refinement (inoculation method) is widely applied for research and industry. Due to its commercial and engineering’s significance, extensive research advances on either investigating the mechanisms/theories of grain refinement or developing effective grain refiners for diverse cast metals/alloys. Actually, work on this field have been carried out for over six decades, which involve with Al, Mg, Fe, Ti, Cu, Sn, Zn and their alloys. However, there is still no full consensus on the mechanisms/theories of grain refinement. Moreover, some new grain refiners, developed based on the current theories, cannot generate satisfying refining efficacy. Based on these considerations, this project firstly reviews the characteristics of effective grain refiners from four perspectives: wetting configuration, segregating elements, crystallographic matching, and geometrical features. Then, the current mechanisms/theories on the grain refinement of cast metals/alloys are revisited, including the peritectic-related theory, the hyper-nucleation theory, the inert substrate theory, and the constitutional supercooling (CS)-related theory. Meanwhile, both the modelling (deterministic- and probabilistic modelling) and the nucleation crystallography in the grain refinement of cast metals are also explored in terms of their recent development, respectively. Finally, the latest development in the grain refinement of cast Zn and its alloys is individually progressed because of limited literature. All these fundamental studies can be carried out in Zn, Ti, Al, Mg, Cu, Fe and their cast alloys.

(3) Characterization, thermodynics, kinetics and design of low-densigy high-entropy alloy An enormous amount of scientific knowledge has been generated on the conventional alloys containing two constituents (solvent and solute). However, there is limited knowledge about the alloys that have more than five constituents in equiatomic (or near-equiatomic) ratios, such as solid-solution high-entropy alloys (HEAs). As functional and structural materials, the low-density nanocrystalline HEAs have many potential cryogenic applications in aerospace, transportation and energy-saving. Meanwhile, the HEA theories can be extended to ceramics, polymer and even liquid. In this proposal, a specific low-density HEA is firstly developed as a low-density HEA using thermodynamic method, i.e. Thermo-Calc®. This development is based on four considerations: (a) high strength-to-weight ratio, (b) low cost, (c) potential cryogenics, and (d) HEA-formation criteria. Then, the fundamental investigation (including microstructural evolution, phase formation, deformation behaviour, cryogenic response, crystal mechanics, solute segregation and grain refinement) will be carried out in the developed low-density HEA. Moreover, the cryogenic-property, crystallography, compositional and microstructural characterisation of such HEAs are expected to be progressed using advanced techniques. These techniques include high-resolution scanning electron microscope (HR-SEM), transmission electron microscope (TEM), high-resolution backscattered diffraction (HR-EBSD), electron contrast channelling imaging (ECCI), atom probe tomography (APT), focused ion beam (FIB) and synchron X-ray tomography (if applicable). In addition, the fundamental studies in this new revolutionary research field is very significant, because it promotes to design an unprecedented family of low-density nanocrystalline HEAs with unexpected properties such as high stability, interesting cryogenic or high strain rate etc. Furthermore, it will generate new scientific and engineering contributions to the fields of metallurgy, physics, materials and characterisation.

(4) Strengthening materials by engineering high-density nanoscale interfacial structures Recently, some novel materials, i.e. metallic nanolaminates, high-entropy alloy, matal/nanoparticle composites, have attractive prime demand in energy, defence, nuclear, transportation and aerospace industries. Dislocation-interfaces are almost involved in all these novel materials with a wide range of crystal structures during service. They play a fundamental role in material properties such as strength, fracture, work hardening, and damage evolution. In order to address their performance and reduce materials’ failure under different service conditions, better analysis/predictive tools are required in terms of dislocation-interface behaviour. Currently, a lot of effort is being devoted to developing the analysis/predictive tools, which entails (a) in-depth understanding of the physical mechanisms of dislocation-interface interaction and (b) efficient numerical tools to predict dislocation-interface evolution from nano- to microscale. The improved analysis/predictive tools will promote to design more advanced materials with enhanced properties. Through this project, we will contribute significantly towards improving these analysis/predictive tools by providing the scientific evidence behind dislocation-interface interaction and by establishing improved numerical models to predict dislocation-interface failure during service. In addition, the development of advanced nanolaminate materials with enhanced properties will also be investigated based on dislocation-interface interactions.

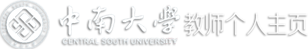

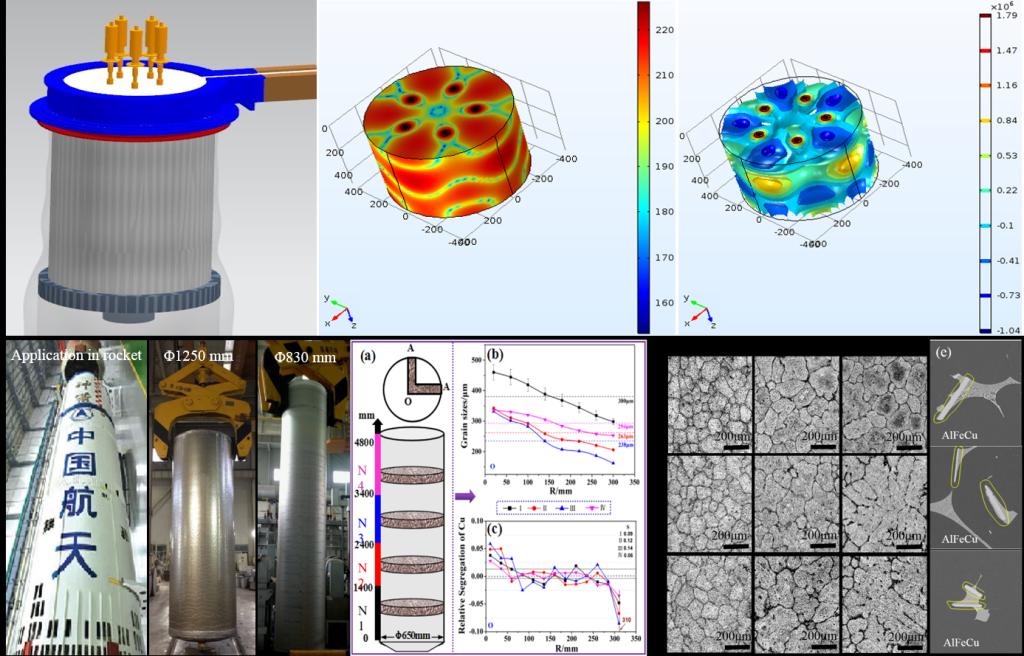

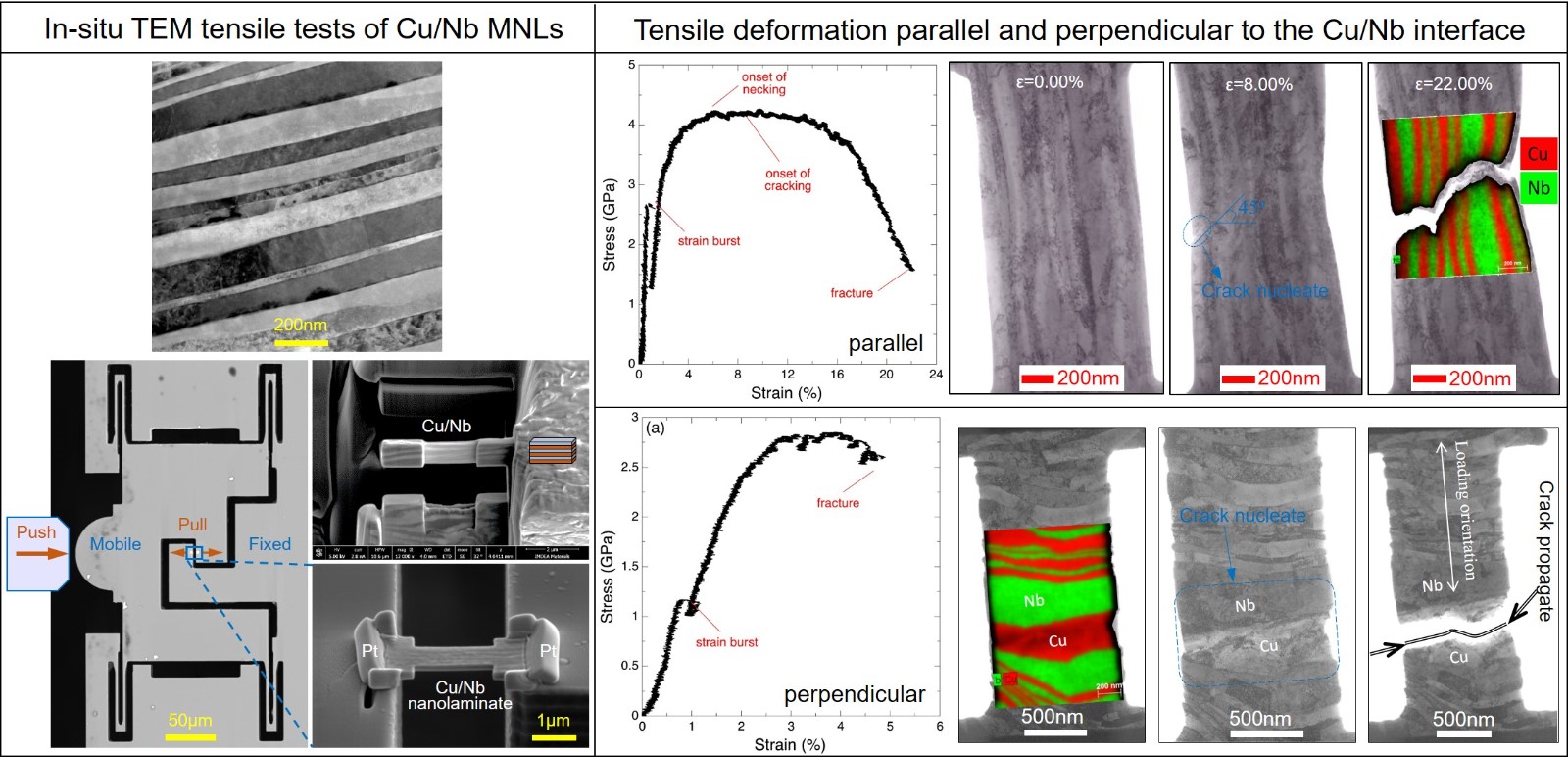

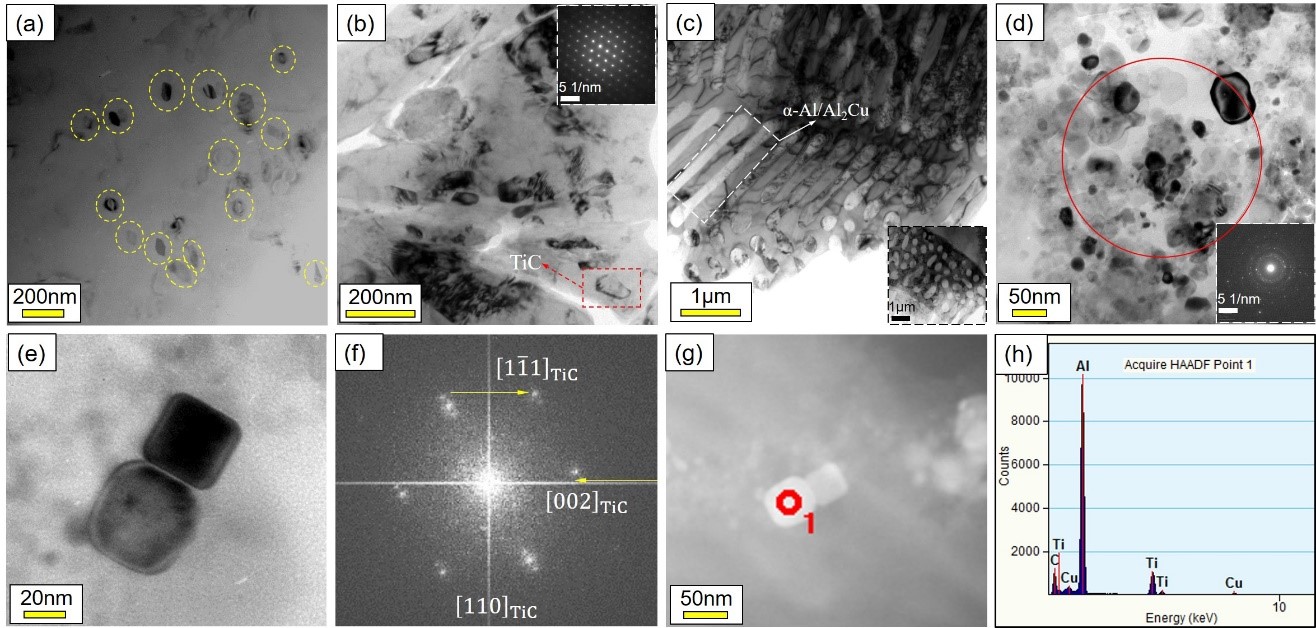

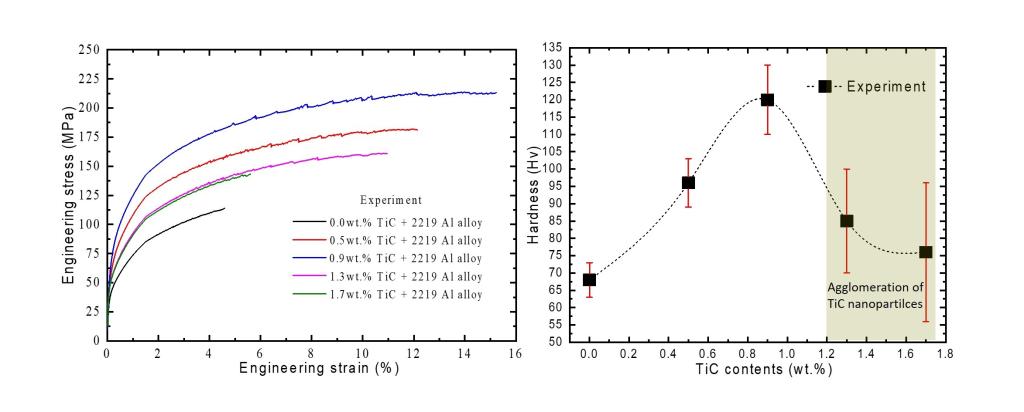

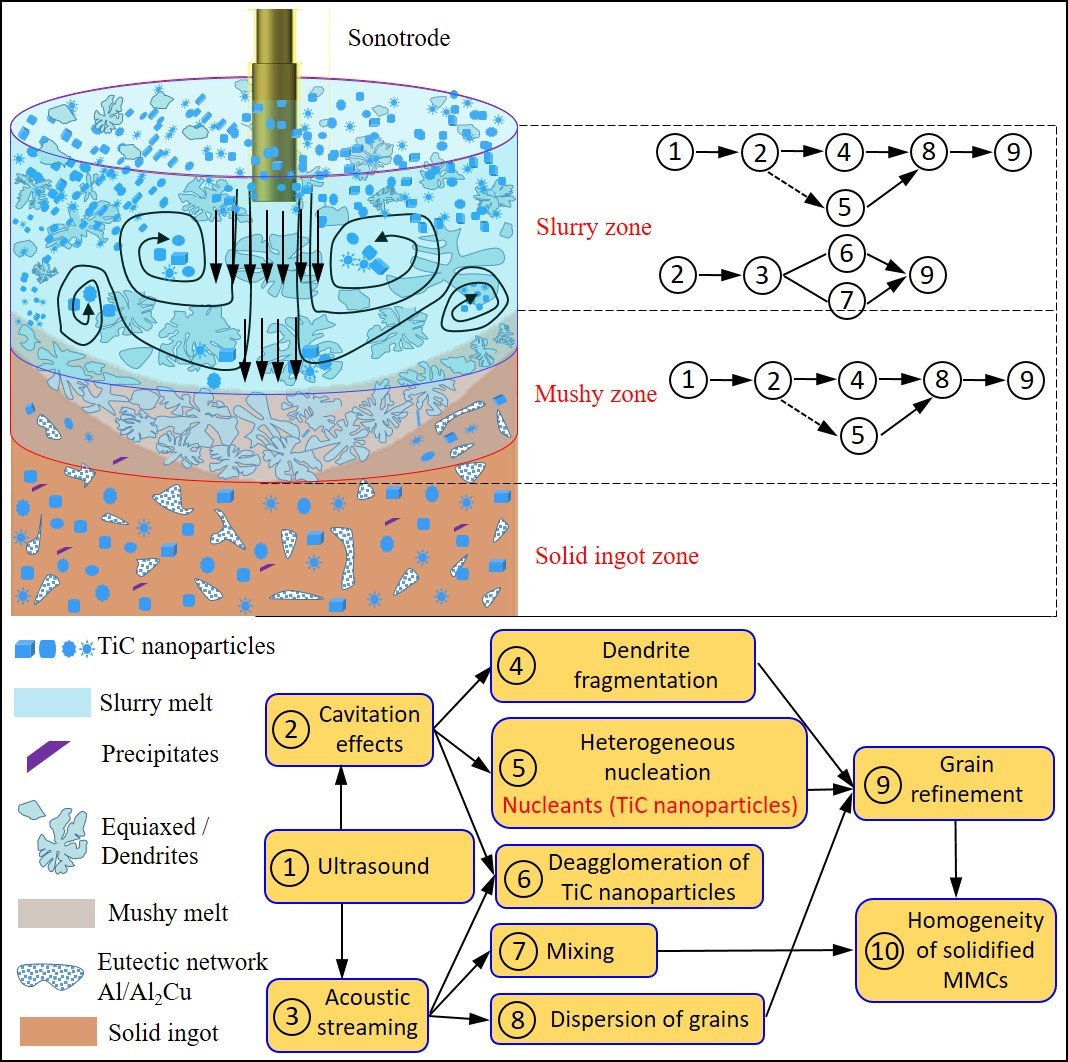

(5) Manufacture of large-scale high-strength Al-Cu alloy ingots using power ultrasound: Interaction boundary and Controlling mechanism The large-scale ingots have significant application in aerospace and high-speed trains. However, some problems, i.e. cracking, coarsening and segregation, impede their downstream plastic processing. Regarding such challenges, we propose a novel “array ultrasonic-assisted casting technique”, and investigate its 3-D influence boundary and associated solidification mechanism, which provides insights to develop the ultra large-scale casting technique. Based on the large-scale high-strength Al-Cu alloy ingots, a series of tasks will be accomplished as follows: (a) To obtain the optimum configuration and number of multiple ultrasonic-generators using mathematic modeling; (b) To investigate the distribution, resonance, distortion and attenuation of the multiple coupling ultrasonic in the 3-D melt during solidification; (c) To characterize the 3-D boundary of the ultrasonic-induced synergies effect, and to provide the way of attenuation compensation; (d) To determine effects of the multiple coupling ultrasonic on the dynamic disturbance of both melt and temperature during solidification, and to calculate the threshold value for cracking; (e) To elucidate the role of multiple coupling ultrasonic on the nucleation dynamics and growth kinetics of α-Al, θ-CuAl2 and other Mn-riched precipitates; (f) To study the role of multiple coupling ultrasonic on the micro/macro segregation of Cu, Mn and Zr/Fe during solidification; (g) To verify the proposed large-scale casting technique by solidification experiments and materials characterization. (6) Characterization and Modelling of dislocation-INterface Interactions in MetAllic Laminates at multiple scales The mechanisms of deformation and fracture in Cu/Nb nanoscale multilayers manufactured by ARB were study by means of tensile tests within the TEM in orientations parallel and perpendicular to the layers. Plastic deformation by confined layer slip (CLS) was found in both orientations for Cu and Nb layers and started in both orientations with a strain burst at an applied strain of ≈ 0.75%. Nevertheless, plastic deformation was rapidly localized in a thicker (and, thus, softer) Cu layer in the specimens deformed in the perpendicular orientation. As a result, the strain hardening in this orientation was limited and failure was brittle and took place by the sudden propagation of crack in this layer at an applied strain of 4.5%. In the parallel orientation, both Cu and Nb nanolayers deformed homogeneously up to an applied strain of 8%. Localization of the deformation in one external Cu layers led to the formation of a crack but crack propagation was stopped at the Cu/Nb interfaces. Significant crack blunting and emission of dislocations took place before the crack could propagate through the Nb layers and failure took place by the coalescence of this crack with another crack coming from the opposite surface in a different plane through a shear crack at 45º. As a result, the Cu/Nb nanolaminate deformed parallel to the layers presented a ductile behaviour with failure strain of 22% and significant necking before fracture. Taper-free InP twinning superlattice (TSL) nanowires with an average twin spacing of ~ 13 nm were grown along the zinc-blende close-packed [111] direction using metalorganic vapor phase epitaxy. The mechanical properties and fracture mechanisms of individual InP TSL nanowires in tension were ascertained by means of in-situ uniaxial tensile tests in a transmission electron microscope (TEM). The elastic modulus along the [111] orientation was 87 ± 17 GPa, while the fracture strain was 2.9 ± 0.3% close to the one reported in ZnO nanowires (~5%) but smaller than that of GaAs nanowires (10–11%). The tensile strength increased from 2.15 to 2.90 GPa as the nanowire diameter decreased from 250 to 210 nm. Fracture was brittle in all cases and occurred by the propagation of a crack along the twin boundary interface. No evidence of inelastic deformation mechanism was observed neither in the experimental stress-strain curve nor in the TEM images before fracture. MD simulations of the tensile deformation of untwinned and twinned InP nanowires of different diameters (12 to 30 nm) at 300 K were carried out to assess the experimental data. The elastic modulus obtained from the simulations (84 GPa) was fairly independent of the diameter and close to the experimental values. The failure strain and the tensile strength of the twinned nanowires in the MD simulations (~10% and ~6.7 GPa) were much higher than those observed experimentally but smaller than those simulated for unwinned nanowires. Moreover, the simulations did not show any evidence of non-linear deformation mechanisms prior to fracture, that was triggered by the nucleation and propagation of a crack at the twin boundaries, in agreement with the experimental observations. Thus the presence of twins limited the strength of InP nanowires. (7) Microstructural evolution and mechanical properties of the AA2219/TiC nanocomposite manufactured by ultrasonic solidification The mechanical properties of metallic matrix composites can be tailored through the microstructural modification between metal matrix and reinforcing particles. In this work, the AA2219/TiC nanocomposite containing 0, 0.5, 0.9, 1.3 and 1.7wt.% TiC nanoparticles were individually manufactured using the ultrasound-assisted solidification technique. There existed an optimal addition level of TiC nanoparticles (0.9 wt.%) beyond which grain coarsening occurred. TiC nanoparticles were observed to reduce the average grain sizes of α-Al matrix alloy by 61%. Meanwhile, 0.9wt.% TiC nanoparticles corresponded to the maximum tensile strength and hardness. When the addition level reached over 0.9 wt.% in the 2219 Al alloy matrix melt, the TiC nanoparticles tended to agglomerate in a form of condensed clusters, which cannot be well dispersed by ultrasonication due to the increasing viscosity. Such agglomerating TiC nanoparticles deteriorated the tensile strain and hardness of AA2219/TiC nanocomposite. Then, five major potential strengthening mechanisms in AA2219/TiCMMCs was quantitatively analysed, including grain refinement, Orowan strengthening, load transfer effect, mismatch of thermal expansion, and mismatch of elastic modulus. Analysis shows that Orowan strengthening acts as the most dominant strengthening mechanism, followed by another comparable strengthening mechanism from the mismatch between the thermal expansion of α-Al matrix and TiC nanoparticles. The other three strengthening mechanisms induced very limited improvement in mechanical properties. Besides acting as reinforcing agents, the TiC nanoparticles also possess very high potency as heterogeneous nucleation sites. The relevant nucleation potency was validated by crystallographic investigation using the edge-to-edge matching model. Finally, the grain refining mechanism ofα-Al matrix alloy was unraveled in terms of the nucleation crystallography and the ultrasonic cavitation. |

|