1.The theory of micro injection molding

1.1 Study of fountain flow in micro injection molding

Objective: Study the flow velocity and pressure distribution in the area of fountain flow

The velocity vector distribution graph of flow Velocity vector distribution considering the surface tension

Pressure contour figure of the microfluidic static model Pressure contour figure cosidering surface tension

Results

◇ Distribution of velocity and pressure of Newton fluid and non Newton fluid are same in the fountain region;

◇ In the micro scale conditions, fountain effect is still a pure fluid dynamic phenomena;

◇ The impact of surface tension on velocity pressure distribution in the region of the fountain flow is small, but produce large deformation in the shape of the leading edge of the fluid.

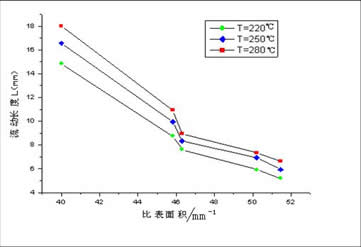

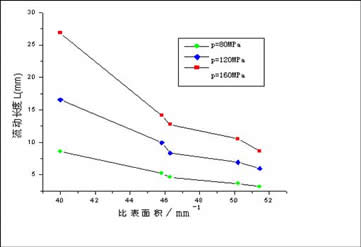

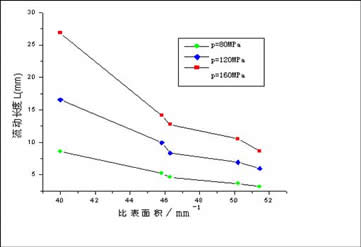

1.2 Effects of micro parts sectional shape on the micro fluid flow performance

Objective:Effects of micro channel cross-sectional shape of the fluid flow properties of non-isothermal non-Newtonian

Results

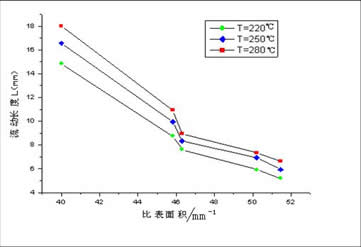

◇ The length of the flow in micro channel is inversely proportional to the specific surface area of the flow channel;

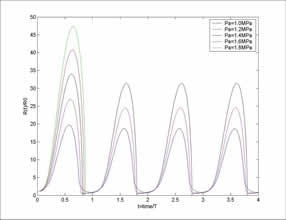

◇ The melt temperature and injection pressure have greater impact on the length of the microfluidic flow of small specific surface area;

◇ Injection pressure has maximum impact on the length of microfluidic flow.

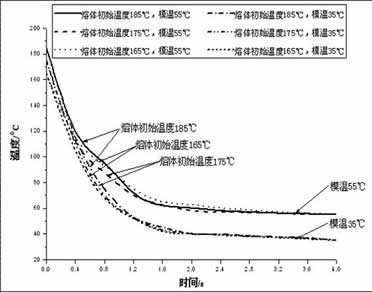

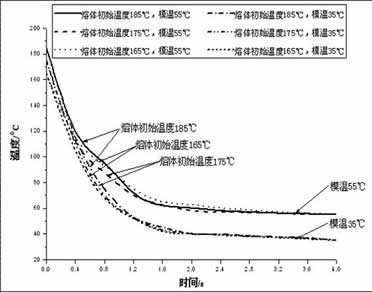

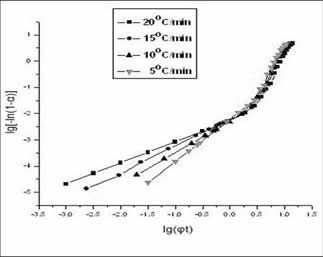

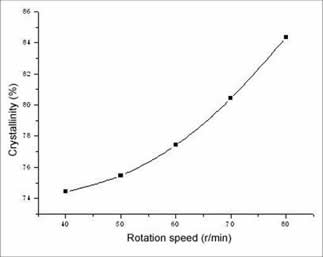

1.3 Study on polymer microfluidic crystallinity

Objective:Considering impact of the perspective of crystallinity on optimization of micro-injection molding process parameters, offers a new way spreading the advantages of material forming.

Results

◇ The mold temperature has a great impact on the molding process, while the impact of melt temperature is small;

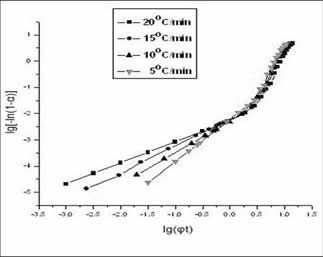

◇ Non-isothermal crystallization kinetic curve is linear relationship only in the early crystallization;

◇ Crystallization cooling rate has a greater impact on the crystal nucleation and growth mechanism in the early time, while smaller effects in the late time;

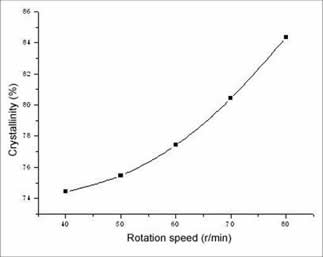

◇ Shear rate promots the formation of shear-induced crystallization, increasing as shear time increases;

◇ The degree of crystallinity increased with increasing initial melt temperature.

2. Polymer ultrasound plasticizing process

2.1 Study of fountain flow in micro injection molding

Objective

◇ Research on mechanism of polymer ultrasound plasticizing process;

◇ Research on the effects of polymer ultrasound plasticizing process;

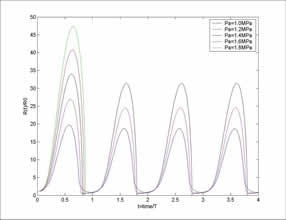

Test equipment of ultrasound plasticizing process The numerical results of ultrasound plasticizing process

Results

◇ Distribution of velocity and pressure of Newton fluid and non Newton fluid are same in the fountain region;

◇ In the micro scale conditions, fountain effect is still a pure fluid dynamic phenomena;

◇ The impact of surface tension on velocity pressure distribution in the region of the fountain flow is small, but produce large deformation in the shape of the leading edge of the fluid.

3. Micro-electroforming technology

Objective

◇ Research on electrodeposition theory, develop a precision electroforming equipment for special manufacturing of the micro-injection molding core;

◇ Solve the uneven distribution of thickness, poor surface quality, low deposition rate of the micro electroforming.

Results

◇ Simulation modeling, forecasting micro electroforming mold core thickness distribution, thickness deviation can be controlled within 15%;

◇ Develops a new precision electroforming equipment, which can improve the surface quality of the micro core with the deposition rate to 2x.